The Fiber Traceability Initiative – Towards Full Traceability in Fashion

What if product information from the entire wool value chain – from sheep farm to final garment – could be traced? What if this information could then be made available with a simple QR code placed within garments? In The Fiber Traceability Initiative, a first version of a digitally traceable wool supply chain is developed, based on global standards for product identification. The aim is to contribute to new, sustainable business models, conscious consumer choices, and longer garment lifespans. And not least, to scale up and spread the solution to multiple value chains and partners.

The Initiative has developed a proof of concept for a digitally traceable merino wool value chain. Photo: Martin Schmidli, Unsplash.

The Issue

The fashion industry produces 100 billion new garments every year, half of which are discarded within 12 months. Despite the potential of biobased materials, most clothing today consists of virgin, fossil-based synthetic fibers, which pose significant environmental challenges. The fashion and textile industry also struggles to establish basic levels of traceability throughout its value chain. In the wool industry of today, for example, traceability is limited to the country of origin and there is no guarantee or certification to ensure that the wool has been produced sustainably and according to high animal welfare standards.

Several new EU regulations have been put in place to safeguard the environment and consumers, opening a path towards responsible production and consumption in the fashion and textile industry. However, companies struggle to find practical ways to implement them.

Our Solution

The Fiber Traceability Initiative has developed a beta version of a digitally traceable wool value chain. The project has implemented digital data collection and sharing throughout the entire production chain – from sheep farms in South Africa to scouring plants, spinning mills, dyeing units, and knitting factories in Europe. The next generation of QR codes are sewn into the garment, which can be scanned by buyers or customers in the store, providing a comprehensive view of the product’s journey, including verified Responsible Wool Standard certification, which validates farms based on animal welfare, environmental, and social aspects. The brand’s landing page also includes recommendations for care, repair, and resale.

The Initiative’s partner VirtualRouteZ compiles all the data on its digital platform. The technical solution uses GS1 standards to create a unified, neutral, and global framework for product identification and labeling, ensuring system interoperability.

The solution is a beta version of a digital product passport, preparing all actors for upcoming EU legislation regarding digital product passports. The project also explores how increased transparency enables new business models that promote sustainability. Furthermore, it assists companies in complying with the EU’s textile strategy and the Ecodesign Directive, including the implementation of digital product passports, a forthcoming EU requirement that will affect nearly all products on the European market.

The Fiber Traceability Initiative is designed to allow for scalability, with the hope of inspiring greater transparency in the fashion industry globally and opening up opportunities for more interested fashion brands and their value chains, in both knitted and woven sectors.

A QR code powered by GS1 is sewn into the garment. This code reveals the product's journey, including its RWS certification, which ensures animal welfare, as well as environmental and social standards at the sheep farm. Photo: Johan Bävman

Results

- Achieving full traceability and transparency throughout the wool value chain.

Through this solution, wool garments in Filippa K’s 2024 autumn and winter collection for 2024 have full traceability. - Implement a standardized, digital business language and interoperability throughout the entire value chain.

GS1 standards are implemented in scouring facilities, spinning mills, and manufacturing suppliers. - Make production and sustainability data accessible to all stakeholders, from sheep owners to consumers.

All data is embedded in a QR code powered by GS1 within the garments. - Paving the way for companies to implement Digital Product Passports.

The solution prepares everyone in the value chain to align with upcoming EU legislation on Digital Product Passports. - Product-based information on care, repair, and resale within the garments to strengthen customer relationships and increase the longevity of the garments.

Filippa K enhances customer information through the landing page. - Driving the transition towards a circular economy and inspiring transparency in fashion.

The solution enables new business models with more efficient use of wool and longer garment lifespans.

Our Work

The venture is a collaboration between actors from the entire value chain. The Initiative is lead by Axfoundation, in collaboration with the global non-profit standard organization GS1 Sweden, Swedish fashion house Filippa K, and technical partner VirtualRouteZ. Enabling label supplier is Trimco. The project is also supported by Textile Exchange and has been accepted into the Nordic Council of Ministers’ Nordic Circular Accelerator, which helps Nordic companies share data and collaborate to maximize business value in a circular economy.

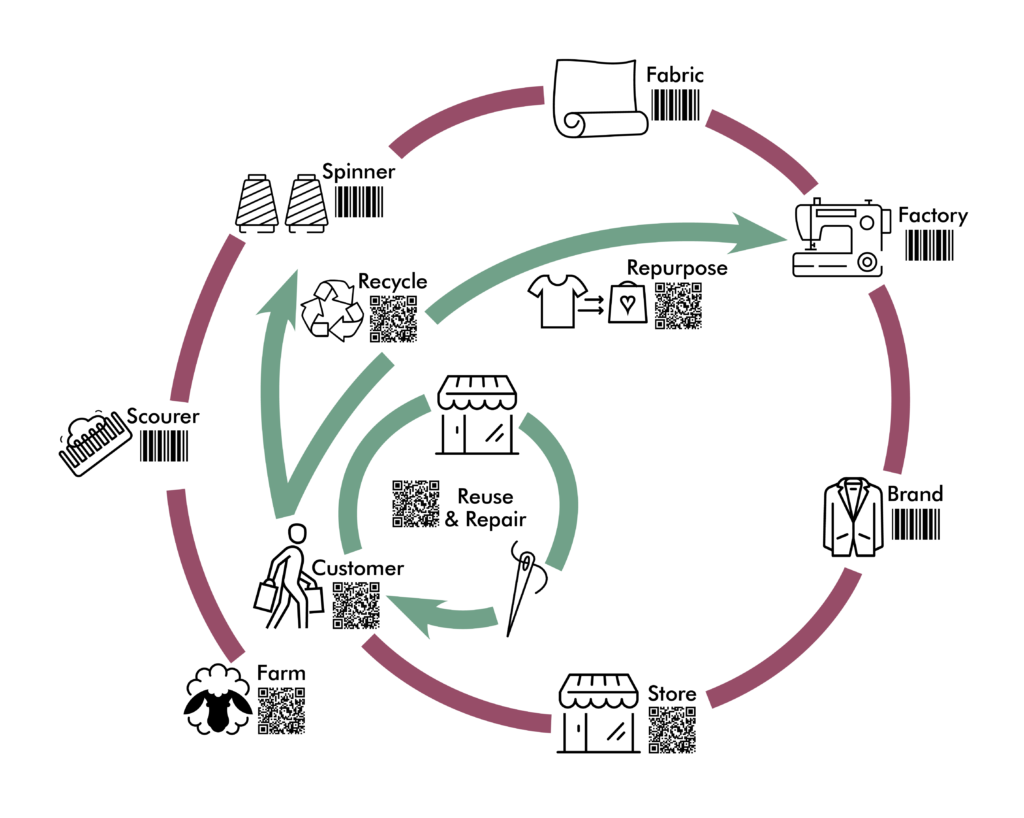

The envisioned full circular process from farm to store and beyond the shelf. The inner green arrows illustrate processes of reuse and repair, remake and recycle. In the future, these steps will also be digitally traceable.

This project serves as a springboard for brands that are preparing for the upcoming legislation. Traceability and transparency also provide business advantages and contribute to sustainable market structures.

– Stina Behrens, Project Manager Future Materials, Axfoundation

EU Regulations Towards a Sustainable Textile Industry

The EU has adopted multiple regulations and directives to ensure product safety and traceability across various industries, including the textile sector. The purpose is to safeguard the environment and consumers while promoting responsible production and consumption. By implementing traceability systems, companies can demonstrate compliance with stringent standards and rules. The Fiber Traceability Initiative’s solution aims to assist companies to adhere to regulations such as:

- The Textile Strategy: The EU Parliament passed the new Textile Strategy on June 1, 2023, with stricter requirements on the textile industry to achieve social and environmental sustainability. The strategy requires, among other things, that producers will have the responsibility to ensure that textiles can be repaired, reused, or recycled.

- The Ecodesign for Sustainable Products Regulation: This legislation will require a Digital Product Passport (DPP) for most goods available on the European market. The objective is to promote sustainable manufacturing and consumption, speed up the transition to a circular economy, and facilitate traceability and transparency for products.

Partners

Axfoundation, Filippa K, GS1 Sweden, VirtualRouteZ. Enabling label supplier is Trimco.

Suppliers who have participated in the project and implemented the solution are the sheep farms Coeja, 3GD, Gildenhuys, Loubser Koch, Grass Co., Bibbey (South Africa), the scouring facility Lemperiere (Bulgary), the spinning and washing facilities Tollegno and Millefilli (Italiy), and the garment manufacturer Trico Point (Romania).

The Fiber Traceability Initiative is welcoming more brand partners to join the journey. For more information, do not hesitate to reach out to the Pproject Manager Stina Behrens.